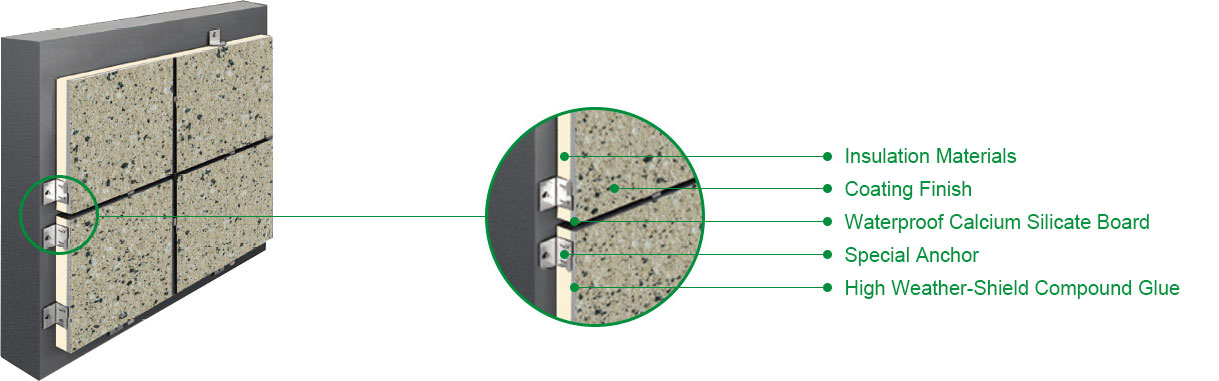

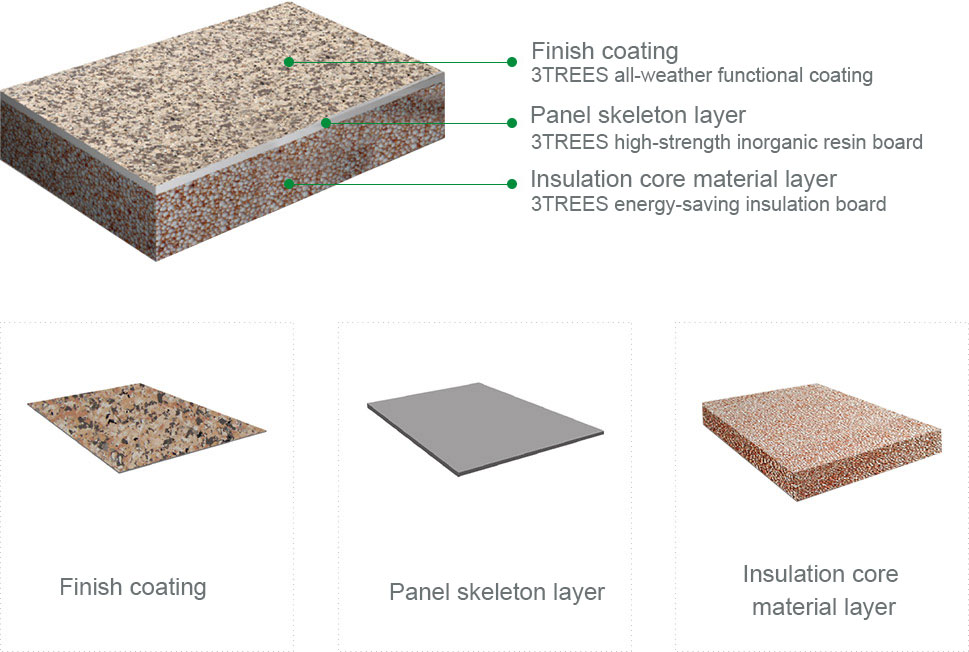

3TREES’s insulated decorative board system is mainly composed of insulated decorative board, bonding mortar and supporting anchor parts. It can be fixed onto building structures by pasting + anchoring, without the need for separate construction of the insulation, moisture-proof, protective, anti-corrosion or decorative layers.

One-time construction can realize the functions of heat preservation, energy conservation, protection and decoration of buildings.

The insulation materials and calcium silicate boards are bonded by special composite glue, with constant pressing for 3-4 hours with an 80T cold press. This can ensure the close bond of panels and the insulation layer.

There are 4 types of commonly used insulation materials:Rock wool insulation board (Y),Expanded polystyrene board (EPS) ,

Graphite polystyrene board (GEPS) ,Polyurethane foam board (PU).

The density of insulation materials must be in accordance with JG/T287-2013 The Materials of External Thermal Insulation Systems Based on Insulated Decorative Panel

The system is bonded to building structures with special bonding mortar. The pull-out value between the substrate bonding mortar and the wall must be tested on site.

The seam width between panels may be designed as 8-15mm, which can release system stress better. A foam bar is used to cut off the heat in the seams, and the high weather-shield silica sealant is used for sealing and waterproofing.

The insulated decorative panel system can be arranged horizontally or vertically according to the building facade style. It is necessary to comprehensively consider system safety, construction convenience and the principle of minimum loss. The conventional specifications are 600mm*800mm, 600mm*900mm, 600mm*1200mm, etc.

Insulated decorative boards are a new type of chemical building materials which integrate decoration, energy saving, fire prevention, waterproofness and environmental-friendliness into one body.

Their characteristic is one-off completion at the factory rather than the traditional onsite construction. Therefore, they offer the advantages of stable quality batch, fast construction and less impact from the environment.

These boards are energy-saving, environmental-friendly, widely applicable, and also possess great development potential and market prospects.

High degree of product assembly, fast application, and good for on-site material management

3TREES’s insulated decorative boards have undergone the mechanized processing of insulation and finishes in the factory, thus reducing the working procedures and time for workers' on-site operation, and improving construction efficiency. Compared with traditional coatings and insulation, the construction period of the insulated decorative boards is at least reduced by more than half, which makes the exterior wall decoration technology modern and scientific; the boards also shorten the cycle of working capital and activate more funds. In addition, by integrating various materials into one, the boards can help on-site material management and reduce material waste and on-site inventory pressure.

3TREES itself produces all the insulation panels and finish materials related to the insulated decorative boards, which ensures good compatibility between the products, and good insulation and weather shield performance.

Compared with traditional stone materials and curtain walls, 3TREES’s insulated decorative boards possess more insulation functions. According to different regional requirements, different board thicknesses can be selected, which can fully meet the requirement of 65-75% energy saving. 3TREES’s insulated decorative boards are highly weatherable and sufficient to resist acid rain and salty fog.

Diversified Finishes with No Color Differences

The finishes of 3TREES’s insulated decorative boards undergo large-scale processing in the factory, thus greatly reducing the requirements of many types of finishing technology in respect of site climate, construction personnel and equipment, and can compound various finish layers. Compared with traditional stone materials which have big color differences, 3TREES’s insulated decorative boards ensure overall uniformity for engineering finishes.

High Safety

Compared with traditional curtain walls and thin plastering, 3TREES’s insulated decorative boards have less weight, which reduces the load of substrate walls and makes the system safer.

Good Crack Resistance

3TREES’s insulated decorative board panels are calcium silicate boards, which possess excellent cracking resistance, and each part is connected with weather-shield silicone sealant, so as to avoid surface cracking caused by insulation materials, seams and temperature difference between day and night as happening with traditional modes of insulation.

Asbestos-free calcium silicate boards are adopted for 3TREES’s insulated decorative board panels. In the production process, resin infusion technology is used, which can give the panels higher strength, lower water absorption, better durability and complete flame resistance. For finish coatings, fluorocarbon solid color paint, fluorocarbon metallic paint and granite paint with excellent self-cleaning performance, good weather resistance, no cracking, no chalking, no fading after an outdoor service life of more than 25 years and high decorative features may be used.

Water resistance

Fire resistance

Light weight

Good weather shield

Long durability

Low maintenance cost

With excellent weather resistance, light and color retention, corrosion resistance, chemical resistance and other properties, it is a finish with the longest service life and the best comprehensive performance at present.

In addition to possessing the excellent properties of fluorocarbon solid color paint, this finish is also added with metal pigment to give rise to a strong metal feel. It can produce a decorative effect that is completely consistent with that of aluminum plastic panels.

Featuring rich colors and excellent weather, water and stain resistance properties, it is a new product in the field of building coatings. Besides, it offers the outstanding advantages of color control, short supply cycle, easy to repair, light weight, safety and environmental-friendliness.

It provides a lifelike sense of stone texture and is natural and durable, rich and diverse, persistently clean, and highly stain resistant. It visually enhances the overall elegance and solemnity of buildings.

This is a thick coating made of polymer emulsion polymer and naturally colored sand which can form stone-like texture. It has a natural, steady and stylish appearance as stone, and is highly adhesive, with excellent weatherability, flexibility and impact resistance.

Prefabricated in the factory and integrating insulation and decoration functions into one body

The boards are suitable for use in new office buildings, business buildings, banks, hotels, schools, hospitals, villas, residential buildings and other buildings; energy saving and decoration transformation of old buildings; and are applicable to a variety of substrates, such as concrete, hollow bricks, ceramsite bricks, etc.

| No. | Item | Unit | Indicator | |||

|---|---|---|---|---|---|---|

| Performance Indicators | 1 | Appearance Quality | Color Uniformity | |||

| 2 | Dimensional deviations | Thickness | mm | ±2.0 | ||

| Length | ±2.0/m | |||||

| Width | ±2.0 | |||||

| Diagonal Difference | ±2.0/m | |||||

| Surface Flatness | ±2.0/m | |||||

| 3 | Surface density | kg/m² | ≤25 | |||

| 4 | Bending load resistance | ≥1.5G(G is 7.5kg) | ||||

| 5 | Acid resistance, 48h | No change in coating | ||||

| 6 | Alkali resistance, 48h | No change in coating | ||||

| 7 | Artificial aging Resistance | No shedding or cracking after 2000h | ||||

| 8 | Bonding strength between surface layer and insulation layer | Mpa | ≥0.10(Damage within the insulation layer) | |||

National standard JG/T287-2013 & enterprise standard Q/SKSP 036-2017

The maximum size is 1200×2400, and products of other specifications are cut according to the engineering design.

Keep Dry

Keep Away from Sunlight

Protect Against Rain

Protect Against Moisture

During the transportation of materials, measures should be taken to prevent extrusion, collision and rain.

The stacking height of 3TREES insulated decorative boards shall not be higher than 2m.

Incoming materials should be placed in a dry and cool place in the factory.

Use of damaged or broken boards should be avoided.

It is forbidden to put insulated decorative boards upright for a long time, so as to avoid deformation.

Tel:

Tel: Email:

Email: Address:

Address:

PUT ON RECORDS IN FUJIAN PUBLIC SECURITY BUREAU

NO.35030402009163

PUT ON RECORDS IN FUJIAN PUBLIC SECURITY BUREAU

NO.35030402009163